- Designed and tested with IEEE 32-1972

- All stainless steel resistor elements

- All parts factory assembled.

- Meets sismic zone 2 requirements

- Epoxy based electrostatic powder painted hot-dip galvanised or stainless stain enclosure

- Solid-Steel one-piece top

- Folklift friendly legs and lifting lugs

Resisturk™ Neutral ground resistors are manufactured in accordance with the requirements of the customers at all voltage and current levels in various applications.

In addition to the standard neutral resistance enclosure, they can also be produced with top entry, bottom entry, side entry, locked door, pedestal and high leg. Besides, Ex-Proof Neutral grounding resistors are also produced specifically for explosive atmospheres according to exproof and Atex standards.

It is enough to send us an email to make an neutral grounding resistance calculation and to get technical information. Resisturk™ team will be honored to help you with all your special project needs.

- Operation Voltage : Up to 110kV

- Rated Current : Up to 5000A Single Cabinet

- Ambient Temperature : -40 to +55DegC

- Protection Degree : IP00 to IP55

- Resistor Element : Stainless Steel or SS Alloy

- Enclosure : Galvanised or SS- steel

- Color : All RAL Colors Avalibe

- Special Requirements : Ex-Proof / Atex Std. Production Avalibe ,

STANDARTS:

Ex-proof Standards:

-

- All special type and design Neutral Grounding Resistors can be manufacture according to customer request.

- Please share your RFQ. Our sales team immediately contact you with quotation including drawing

- Please give us inform of your project. Design team will help you to neutral grounding resistor calculation and sizing.

ROUTINE TESTS:

Routine tests* are performed for each product after manufacturing is completed.

- Measurement of DC resistance

- Measurement of insulation resistance between R-G

- Insulation test of resistor blocks

- Thickness measurement of galvanization and/or paint

*a copy of Test Raports are included with each shipped NGRs

TYPE TESTS:

Type tests are also performs in accordance with the customer’s request for the special manufactured products.

- Temperature rise test

- Protection degree test

- Impulse voltage test (1.2 / 50 µs)

OPTIONAL TESTS:

Optional tests are also performs in accordance with the customer’s request.

- Measurement of AC resistance

- Insulation resistance test N-G

- Seismic test (Seismic test table)

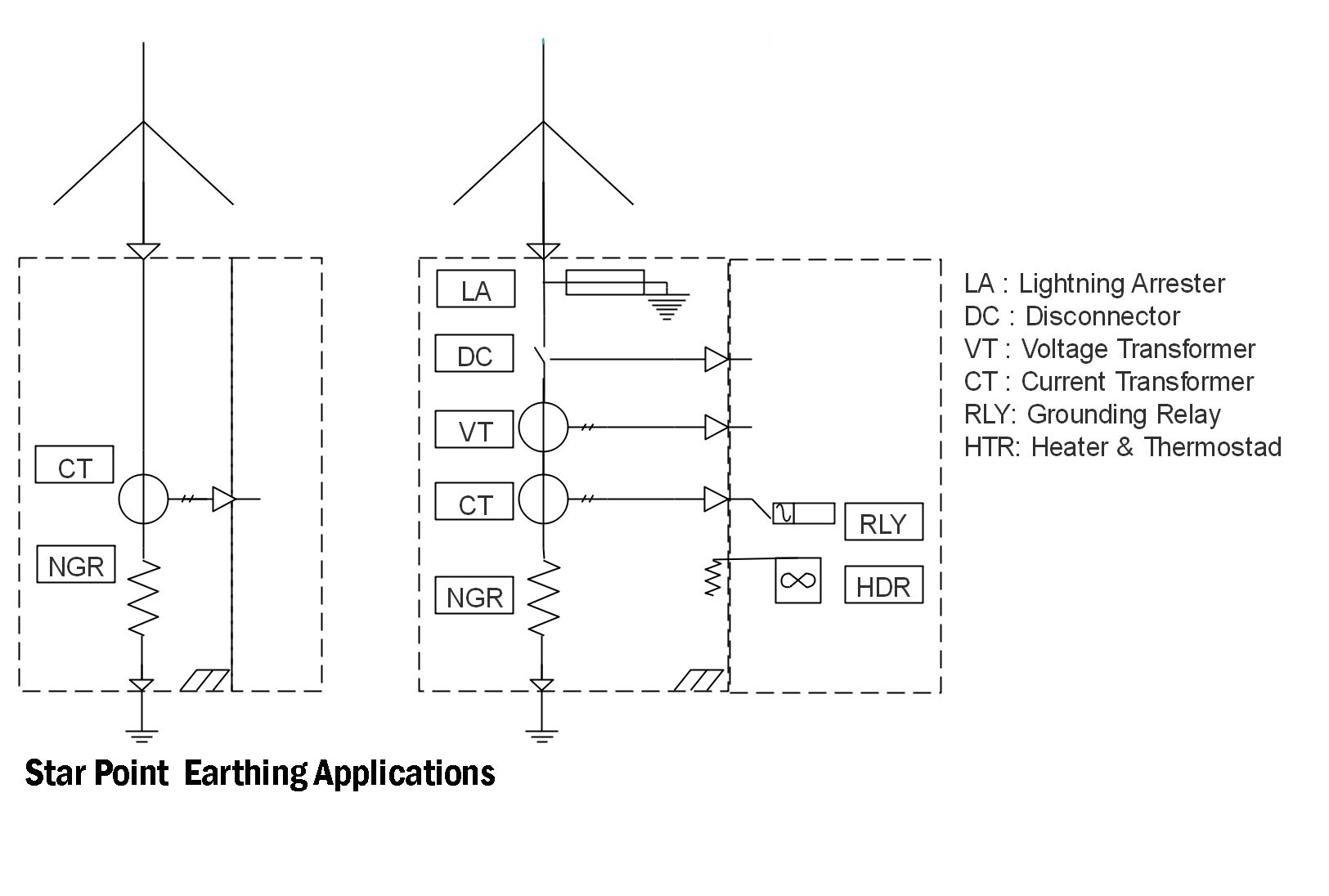

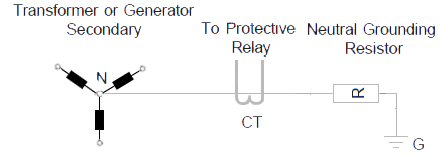

- Current – Voltage Transformer

- Vacuum Contactor

- Elastimold Bushing

- Heater and Thermostad

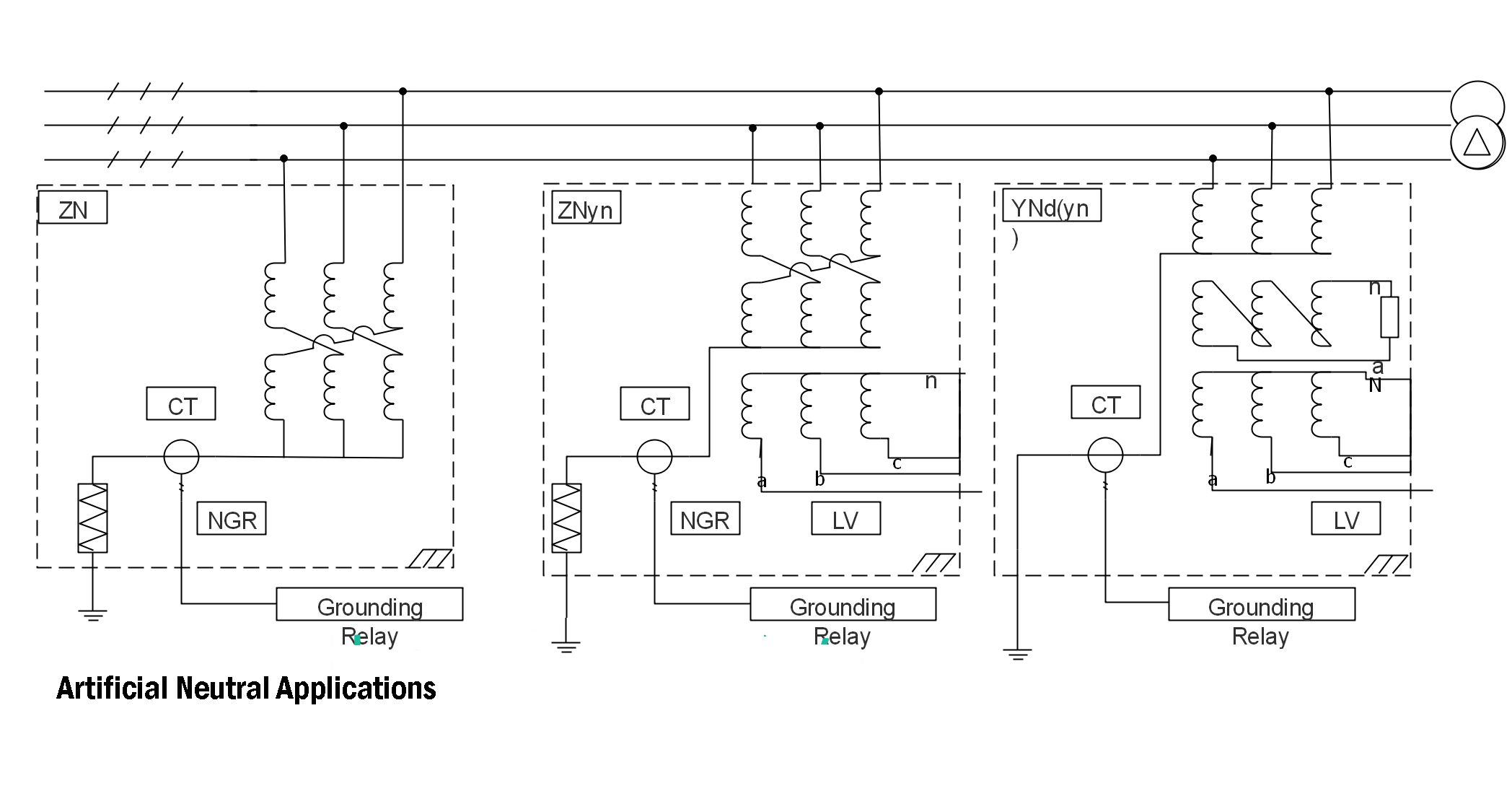

- Grounding Relays

- External Bushing

- Manual – Motorised Disconnector

- Grounding Transformer

Neutral grounding resistors can be manufactured with many additional options according to the type of application used.

Current Transformer and Voltage Transformer:

Primer or secondary is used for measurement or protection. (can be produced at the desired value).

Grounding relays:

In case of earth fault, DRY Contact outputs according to the setting made. They are connected to the primary or secondary of the NGR’s internal current transformers. They are manufactured integrated in neutral grounding resistance panel, Available at the desired voltage level

Manual and motor disconnectors and Vacuum Contactors:

Primer or secondary, is used to disconnect resistances ground connection. Coil Voltage, Number of contacts determined by customer

Panel Heaters:

They are used to protect the internal panel of resistance against very cold environments. They are produced at the desired voltage level.

All custom design are avalibe!

- System Voltage

- Line to Natural Voltage

- Current Rating

- Resistance

- Maximum Time on (sec).

- Input / Output Terminal (Cable/bushing)

- Current / Voltage Transformer ratio(if applicable)

- Special Options specifications.